Understanding the Fundamental Divide

Meanwhile,; The chemical universe is broadly divided into two major categories: *organic* and *inorganic* substances. While organic chemistry focuses on carbon-based compounds typically containing carbon-hydrogen bonds, inorganic chemistry encompasses all other chemical compounds, including minerals, metals, and salts. This fundamental distinction shapes how these chemicals behave in different physical forms, particularly powders and liquids. Organic Chemical Supplier

Organic Chemical Supplier

These Organic compounds, derived from natural sources or synthetic processes, include everything from plant-based materials to complex polymers. Inorganic compounds, abundant in nature, form the basis for vital industries including semiconductors, pigmentation, coatings, fuel, medicine, and chemical manufacturing. Both categories offer unique advantages depending on their physical state and application requirements.

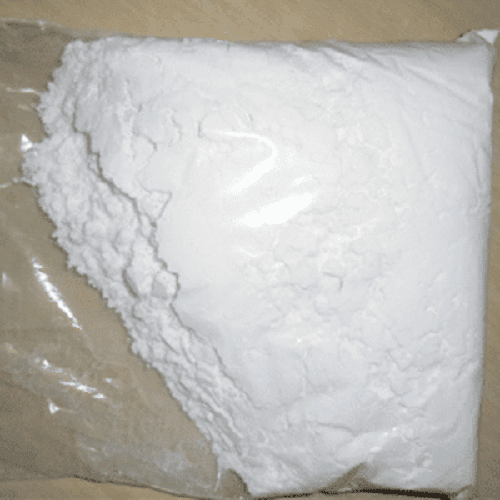

Powder Forms: Organic Powder Chemicals

Organic Powder Chemicals

Quality Organic powders are finely ground carbon-based compounds that offer exceptional versatility. These include:

Pharmaceutical ingredients* – Active pharmaceutical ingredients (APIs) in powder form allow for precise dosing and formulation flexibility

Food additives* – Natural colorants, flavor enhancers, and nutritional supplements

Polymer resins* – Used in coatings, plastics, and composite materials

Agricultural products* – Organic fertilizers and soil amendments

Meanwhile,; Organic powders typically exhibit lower melting points compared to inorganic counterparts and are often more soluble in organic solvents. Their particle size distribution significantly impacts performance characteristics like dissolution rate and bioavailability.

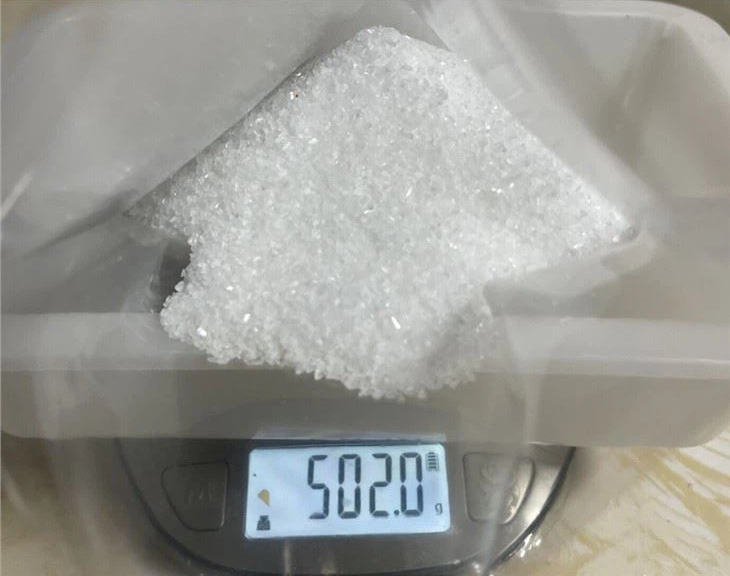

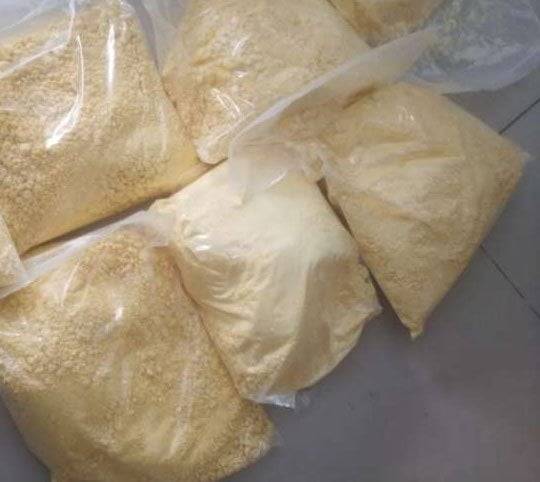

Inorganic Powder Chemicals

Our Inorganic powders encompass a wide range of mineral-based and synthetic materials:

Metal oxides* – Titanium dioxide, zinc oxide, and iron oxides for pigments and coatings

Ceramic materials* – Alumina, silica, and various clay minerals

Salts and minerals* – Sodium chloride, calcium carbonate, and other essential compounds

Catalysts* – Various metal-based catalysts for industrial processes

Our Inorganic powders generally demonstrate higher thermal stability, chemical resistance, and mechanical strength compared to organic alternatives. Furthermore,; They’re crucial in construction materials, electronics, and industrial applications where durability is paramount.

Liquid Forms: The Fluid Solutions

Organic liquids encompass a diverse range of carbon-based compounds in fluid state:

Solvents* – Alcohols, ketones, esters, and hydrocarbons used across industries

Oils and lubricants* – Plant-based oils, synthetic lubricants, and hydraulic fluids

Liquid polymers* – Resins, adhesives, and coating materials

Extracts and concentrates* – Natural plant extracts for food, cosmetics, and pharmaceuticals

This Organic liquids offer excellent solvency properties, making them ideal carriers for various applications. Meanwhile,; Their viscosity, evaporation rate, and compatibility with other materials determine their suitability for specific uses.

Inorganic Liquids

Acids and bases – Sulfuric acid, hydrochloric acid, sodium hydroxide solutions

Salt solutions – Electrolytes, brines, and chemical processing fluids

Liquid metals – Mercury and various metal alloys in molten state

Water-based formulations – Many industrial and cleaning solutions

These liquids often exhibit high ionic conductivity, thermal stability, and chemical reactivity. They’re essential in metal processing, water treatment, and various manufacturing processes.

Application-Specific Considerations

Coatings Industry

The coatings industry beautifully demonstrates the interplay between organic and inorganic materials in both powder and liquid forms. *Organic coatings*, whether liquid or powder, provide excellent adhesion, flexibility, and decorative properties. Furthermore,; They’re typically composed of carbon-based polymeric chains derived from natural or synthetic sources.

*Inorganic coatings* rely on minerals like silica, alumina, and titanium dioxide instead of carbon-based compounds. These coatings offer superior UV resistance, hardness, and thermal stability, making them ideal for high-temperature applications and harsh environments.

Pharmaceutical Applications

In pharmaceuticals, both forms play critical roles. Powder forms allow for precise formulation control and extended shelf life, while liquid forms enable rapid absorption and easier administration. Furthermore,; The choice between organic and inorganic depends on the desired therapeutic effect, stability requirements, and delivery method.

Agricultural Uses

Our agricultural sector utilizes both organic and inorganic chemicals in various forms. Organic fertilizers in powder form slowly release nutrients while improving soil structure, while liquid formulations allow for foliar application and rapid nutrient uptake. Meanwhile,; Inorganic fertilizers provide concentrated, immediately available nutrients but require careful application to avoid environmental impact.

Environmental and Safety Considerations

Meanwhile,; environmental impact of these chemicals varies significantly between organic and inorganic forms. Many organic compounds are biodegradable and derived from renewable resources, but some may contain volatile organic compounds (VOCs) that contribute to air pollution. Furthermore,; Inorganic compounds, while often more stable and less volatile, can persist in the environment and may contain heavy metals or other potentially toxic elements.

Future Trends and Innovations

Recent advancements are blurring the lines between organic and inorganic chemistry. Furthermore,; Organic-inorganic hybrid materials* are emerging as promising solutions across various industries. These composites combine the best properties of both worlds – the flexibility and processability of organic materials with the durability and stability of inorganic components.

Choosing the Right Form for Your Needs

Selecting between organic and inorganic chemicals, and between powder and liquid forms, depends on multiple factors:

Application requirements* – Consider temperature resistance, chemical compatibility, and mechanical properties

Processing needs* – Evaluate mixing, application, and handling requirements

Environmental factors* – Assess biodegradability, toxicity, and environmental impact

Cost considerations* – Balance performance requirements against budget constraints

Regulatory compliance* – Ensure the chosen materials meet industry standards and regulations